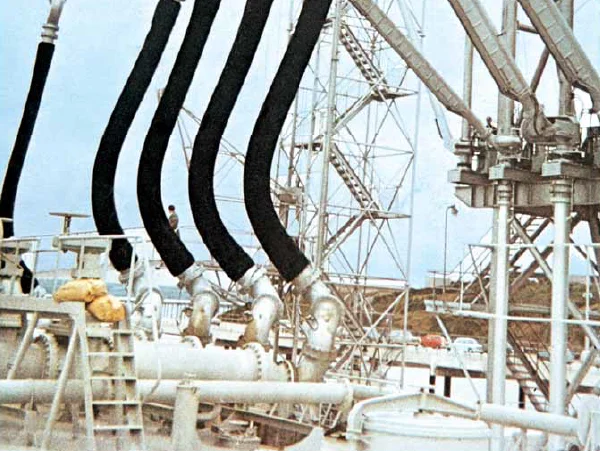

Hoses

Offspring International offers a range of hoses for a variety of fluid transfer applications including oil suction & discharge, LPG suction & discharge, fuel transfer, and suction & discharge of petroleum products.

All hoses produced by Offspring’s partner, MAN Oil & Marine, are manufactured and tested in accordance with industry standards.

These include OCIMF GMPHOM 2009, 5th Edition ‘Guide to Manufacturing and Purchasing Hoses for Offshore Moorings’ as certified by the American Bureau of Shipping (ABS) as well as other applicable standards.

For more information download the Offspring International Offloading Hoses Brochure or take a look at the range below.

Offspring International’s range of hoses includes:

Single Carcass Hoses

MAN Oil & Marine’s Floating and Submarine single carcass hoses are designed for Oil Suction and Discharge.

Single carcass hoses are available with either Steel Cord Reinforcement (Poseidon) or Textile Cord Reinforcement (Nautilus) in diameters between 6-24” (150-600mm) and standard lengths of 30ft (9m), 35ft (10m) or 40ft (12m).

Double Carcass Hoses

MAN Oil & Marine’s Floating and Submarine double carcass hoses are ideal for Oil Suction and Discharge. Double carcass hoses are designed so that if the primary carcass fails the secondary carcass contains the leak and a mechanical Failure Alert Device (FAD) is activated.

Double carcass hoses are available with either Steel Cord Reinforcement (Poseidon) or Textile Cord Reinforcement (Nautilus) in diameters between 6-24” (150-600mm) and standard lengths of 30ft (9m), 35ft (10m) or 40ft (12m).

Hoses for Reeling Systems

MAN Oil & Marine has designed a dedicated hose range of floating and submarine hoses, single and double carcass, capable of being stored on a reel in one or more layers.

FreeFlex Hoses

MAN Oil & Marine’s FreeFlex hose is the result of over 25 years’ experience designing and manufacturing helix-free hoses. As its name indicates, the FreeFlex hose does not have a helical, steel wire body like conventional oil suction and discharge hoses.

The whole carcass is free to flex as necessary to react to the extreme loads that are often applied during handling or service. Once the load has been removed FreeFlex returns to its original shape with no permanent deformation.

Long Length Hoses

Dock Hoses

Offspring International offers Dock Hoses for the suction and discharge of petroleum products, suitable for several onshore applications, such as refineries, shore tanks and across the energy sector.

MAN Oil & Marine Dock hoses exceed the basic requirements of all International rules as their construction is a direct derivate of designs, technology and quality control procedures used in the building of marine hoses for offshore application, with long operational life and total environmental safety in mind.

LPG Hoses

Second Generation (BS EN 1762:2003) of hoses for Liquefied Petroleum Gas in suction and discharge applications.

Hose End Valves

Offspring offers a range of valves for regulating fluid transfer between the hose string and tanker for both oil products and LNG.

For more information visit the Valves and Actuators page or download the Valves & Actuators Brochure.

Ancillary Items

Offspring International supplies a range of ancillary items enabling the safe installation and operation of offloading hoses. These include hose pick-up and hang-off chains, hose floats, spool pieces, camlock couplings, butterfly valves, blind flanges and a hose repair kit.

For more information on Offspring’s range of hoses download the Offloading Hoses Brochure.