Valves and Actuators

Working with valve partner Marine Division, Offspring International offers a range of high quality offshore valves and actuators ensuring safe and efficient fluid transfer operations between pipeline, buoy and tanker for both oil products and LNG.

Valves regulate the flow of fluid throughout the transfer system during operation, as well as preventing water ingress whilst not in use. While operators ensure that each valve in the fluid transfer system is in the required position.

Valves

Valves are essential to the function of loading and offloading systems.

Offspring offers its customers access to the valve ranges of the world’s leading manufacturers to suit the requirements of a variety of offloading systems including SPM, CBM, PLET and PLEM.

Offspring International is able to supply all valves from ball, butterfly, gate (including through conduit), globe, check and plug valves either manual or actuated. All valves supplied by Offspring are designed and manufactured under quality systems in accordance with ISO 9001 and to the applicable international standards.

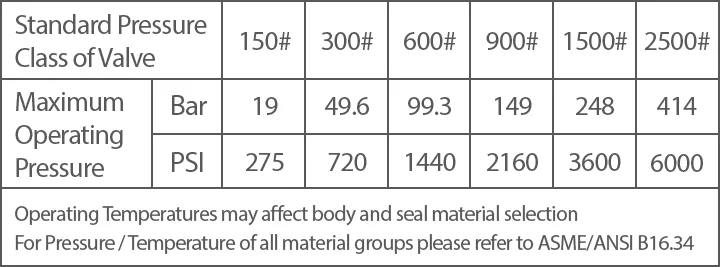

Please find below typical maximum operating pressure per class at ambient temperatures.

Valve Selection

In order to select the appropriate valve and provide reliable transfer operations, Offspring works with the customer to determine as minimum the following details:

- Purpose (On / Off / Control)

- Type

- Pipeline size

- Pressure rating

- End connection

- Process data:

– Design pressure

– Design temperature

– Operating pressure

– Operating temperature

– Body and trim material (if known)

– Process media

– Functionality of the valve (On / Off / Control)

– Special requirements

– Operation (Manual / Actuated).

By determining these vital parameters, Offspring International can supply valves which contribute to a cost-effective system that meets or exceeds the operational performance and required service life.

Actuators

Actuators are utilised for driving valves from open to closed and anywhere in between depending upon the application, control of process system, inaccessibility, emergency shutdown / fail safe, excessive torque and safety, these can either be Manual or Automated.

Working with the customer and valve partner, Offspring ensures an actuator appropriate to the requirements of the system. An actuator must provide enough torque to move and re-seat the valve, as well as, maintaining its position with the minimum power supplied, be able to fully travel either rotary, i.e. 90°, 180° or linear and incorporate protective measures to prevent an oversupply of power.

Offspring offers a range includes:

- Levers / Handwheels

- Bevel

- Worm

- ROV

Automated Actuators

- Linear Actuators

- Quarter-turn Actuators

- Multi-turn Actuators

Valve automation provides terminals with a range of benefits including the ability to pre-set operating positions which can then be optimised with minimal involvement.

For more information on Offspring’s range of valves and actuators & ancillary items download the Valves & Actuators Brochure